A Transportation Management System is not “nice to have infrastructure.”

It’s the operating system of your freight network.

The TMS market is growing fast, driven by cloud adoption, AI, and e-commerce pressure on service levels. At the same time, margins are thin, demand is volatile, and customers expect precise ETAs, proactive updates, and clean invoices.

That combination changes what “good enough” looks like.

If your TMS still behaves like a digital filing cabinet for loads and rates, it will quietly hold you back. In 2026, you should expect much more.

Below is a practical benchmark: what a modern TMS should realistically deliver for a shipper, broker, or carrier that takes transportation seriously.

1. One Version of the Truth, Not Ten Spreadsheets

Data fragmentation is still one of the biggest causes of bad decisions in logistics. Reports live in BI tools, rates sit in Excel, invoices live in accounting, and tracking is stuck in separate visibility portals.

A TMS should give you a single operational truth across:

- Orders, loads, trips, and appointments

- Carriers, contracts, tariffs, and accessorial rules

- Facilities, lanes, and customer SLAs

Events, status updates, exceptions, and PODs

Logistics tech leaders are pushing towards centralized, clean data to power scenario planning, digital twins, and more accurate decision-making. Your TMS is where that starts. If it cannot serve as the core data spine, every “AI” or “analytics” promise later will underperform.

2. Embedded Intelligence, Not Just Static Reports

Most legacy TMS platforms are great historians. They tell you what happened last week.

You should expect your TMS to actively help you decide what to do next, for example:

- Tender grading & freight selection

Scoring tenders and matching them with the right carrier or asset based on margin, service risk, and network balance, not just cheapest rate. - Predictive exceptions

Flagging loads at risk of delay based on historic patterns, lane behavior, seasonality, and real-time signals. - Network forecasting

Looking 3–7 days ahead: where you’ll be long or short on trucks, where customer volumes will spike, and which contracts will get stressed.

Research shows AI in supply chain and transport can cut logistics costs by 5–20% when used for predictive analytics and planning. Those gains don’t come from a “magic AI button”, they come from very specific decision points embedded inside the TMS.

If your TMS only gives you dashboards and leaves all decisions to manual judgment, it’s behind.

Read more: How to Reduce Freight Costs Without Sacrificing Service Quality

3. Real Control Over Cost, Margin, and Freight Audit

Freight audit is moving inside the TMS, not handled as a distant afterthought.

You should expect your TMS to:

- Rate every load using the same logic used at tender time

- Automatically compare AP invoices with planned costs

- Validate accessorials against events (actual detention time, redelivery, TONU, etc.)

- Flag variances above a set threshold and route them to a dispute queue

- Push approved payables and receivables straight into your accounting or ERP systems

Studies on transportation tech show that AI and advanced analytics embedded in TMS platforms are being used specifically to identify inefficiencies, improve rate negotiations, and improve margin visibility.

it’s reasonable to expect your TMS to catch revenue leakage automatically, not just show you that your margin shrank after the fact.

4. Automation That Reflects How You Operate

Every logistics business has its own quirks: appointment rules, customer SLAs, dock hours, required documents, accessorial policies, regional carriers, and internal approvals.

A modern TMS should let you capture that in configurable workflows, for example:

- Auto-assigning carriers based on lane, equipment, customer, and scorecard

- Triggering tasks when certain events happen (delay, temp excursion, border hold)

- Automatically generating emails, portal updates, or SMS to drivers and customers

- Enforcing business rules (“No appointment, no dispatch”, “POD required before invoicing”)

You shouldn’t be forced to hack processes around fixed screens. you should expect your TMS to behave more like a flexible workflow engine on top of solid transportation data.

5. API-First and Ecosystem Ready

Standalone tools are fading. Terminal operators, forwarders, and logistics providers are moving towards integrated, data-driven platforms where TMS, WMS, telematics, visibility tools, and finance systems share data in real time.

From a TMS, that means:

- Open, well-documented APIs for orders, loads, shipments, tracking events, invoices

- Plug-and-play connectors for:

- Load boards and marketplaces

- Visibility and telematics (GPS, ELD, IoT sensors)

- Rate providers and compliance tools

- Accounting and ERP

- Load boards and marketplaces

- Webhooks or event streams so other systems can react as your network moves

In practice, this is the difference between:

| Expectation from a TMS | What It Looks Like in Reality |

| Easy integrations | Standard REST APIs, sandbox keys, and no custom one-off file drops |

| Low friction onboarding of partners | Carriers onboarded via portals + API, not endless email threads |

| Faster projects | Most integrations measured in weeks, not 12–18 month IT programs |

If your TMS still needs custom flat-file exchange and nightly batch jobs for every new connection, you’ll struggle to keep up.

Read more: Logistics KPIs for Performance: What to Track & Why

6. Sustainability and Customer Experience Built-In

Sustainability pressure isn’t going away. Neither are customer expectations.

By 2026, you should expect your TMS to:

- Estimate CO₂ per lane, mode, and shipment, and show trade-offs between cost, time, and emissions

- Support mode shifting (e.g., road to intermodal) and smarter consolidation

- Enable self-service portals for customers and carriers:

- Track & trace with realistic ETAs

- Appointment booking and rescheduling

- Digital documents and PODs instead of email chaos

- Track & trace with realistic ETAs

Some of the strongest AI and logistics trends focus exactly on route optimization, fuel reduction, and better last-mile delivery promises. A TMS that cannot expose those levers to your team and customers will make your sustainability targets much harder to hit.

7. Governance, Security, and Reliability by Design

Transport is now tightly linked to finance, compliance, and customer SLAs. That means your TMS can’t be a fragile point in the chain.

Reasonable expectations for 2026:

- Enterprise-level security (access control, audit trail, field-level controls)

- High uptime and resilience, no daily “TMS is slow again” conversations

- Clear ownership of data, backups, and disaster recovery

This is where cloud-native and platform-based TMS solutions have a real edge: they inherit strong security and reliability foundations instead of trying to bolt them on later.

Read more: Improve On-Time, In-Full (OTIF): Strategic Planning, Smarter Routing & Real-Time Collaboration

So… Where Does FTM Fit?

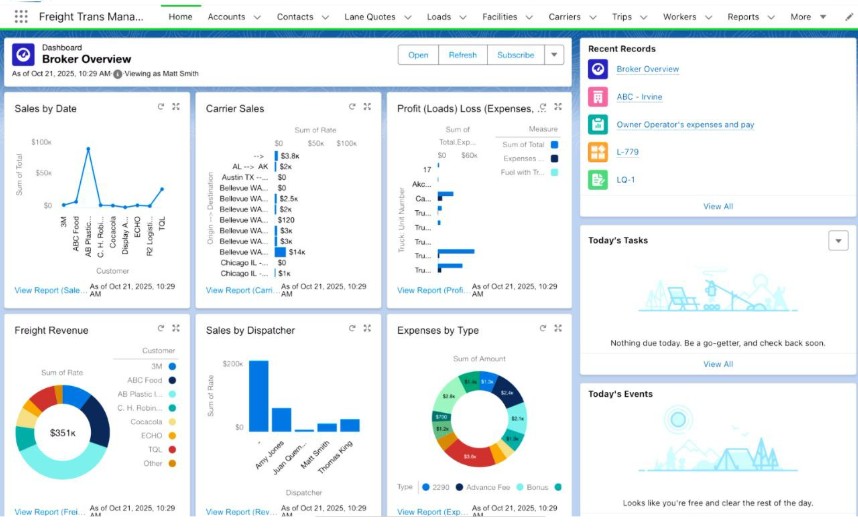

If you’re reading this on FTM, you’re probably already asking the key question:

“How close are we to this 2026 TMS benchmark?”

FTM is built on Salesforce, which gives you enterprise-grade security, uptime, and UI as a base, and then layers transportation-specific capabilities on top, load management, portals, tariffs, workflows, and accounting integrations tailored for shippers, brokers, and carriers.

If you want your TMS to:

- Be your single source of truth

- Embed real decision logic, not just reports

- Automate billing, exceptions, and workflows around how you operate

- Plug into your existing ecosystem without months of custom work

…then it’s worth seeing what FTM actually looks like in your network.

👉 Next step: book a quick demo with the team at FTM and walk through your current TMS gaps. Bring your real lanes, customers, and carriers, we’ll map them to what a 2026-ready TMS should deliver.