B2B logistics used to be predictable.

Orders came in bulk. Lead times were generous. Customers expected delays, paperwork, and phone calls. Transportation was a cost center, not a brand touchpoint.

That world is gone.

Today, B2B buyers expect the same clarity, speed, and reliability they get from consumer platforms. They want accurate ETAs, proactive updates, clean documentation, and fast issue resolution. At the same time, supply chains are more complex, more global, and more fragile.

Managing B2B logistics now means balancing three pressures at once:

- Operational complexity across regions and modes

- Commercial expectations from enterprise customers

- Cost and margin control in volatile markets

This guide breaks down how strong logistics teams handle that reality.

1. Treat logistics as a customer-facing function

In B2B, logistics are no longer invisible.

A late delivery can delay a production line. Missing documents can stall customs. Poor communication can damage a long-term relationship. For many customers, logistics performance is part of how they evaluate your brand.

That changes the role of operations.

Strong B2B teams align logistics with customer experience by:

- Defining service levels by customer, not just by lane

- Setting clear communication standards for delays and changes

- Giving sales and account teams real visibility into shipment status

When logistics is isolated from customer teams, friction appears everywhere. Calls increase. Trust erodes. Escalations become routine.

2. Design around variability, not averages

B2B freight rarely behaves like a clean average.

Volumes spike. Projects start and stop. Customers have unique handling rules. Some lanes are predictable. Others are volatile.

Teams that plan around “typical” weeks struggle when reality diverges.

Better operators:

- Segment customers by behavior and risk

- Separate stable lanes from volatile ones

- Design different playbooks for each category

For example, a recurring plant-to-plant move should be automated and optimized for cost. A project shipment for a new customer should be designed for flexibility and communication.

One-size-fits-all workflows break under pressure.

3. Build a carrier network, not a carrier list

Many B2B shippers treat carriers as a static directory.

In practice, a carrier network is a living system. Capacity changes. Performance shifts. Financial health varies.

Effective teams:

- Track performance by lane and customer

- Maintain primary and secondary options

- Review behavior during disruptions, not only on-time rates

- Adjust strategy based on real outcomes

This turns procurement from a pricing exercise into a network design function.

A cheap rate on paper means little if the carrier cannot recover when something goes wrong.

Read More: Carrier Portal for Faster Freight Operations

4. Make visibility operational, not cosmetic

Visibility is often framed as a customer feature.

In strong B2B operations, it is an internal control tool.

Real visibility allows teams to:

- Identify risk before customers call

- Reassign capacity early

- Prioritize resources during disruption

- Align customer communication with reality

The goal is not a map on a screen. The goal is decision speed.

When visibility data lives outside core workflows, teams still operate reactively. When it is embedded in planning and execution, it changes behavior.

5. Standardize what should be standard

B2B logistics is full of avoidable variation.

Different teams send different documents. Facilities interpret rules differently. Customers receive inconsistent updates. Finance reconstructs reality after the fact.

High-performing teams standardize:

- Order intake formats

- Required shipment data

- Documentation flows

- Exception handling paths

- Status communication rules

Standardization does not remove flexibility. It creates a stable base that allows flexibility where it matters.

Without it, every exception becomes a new problem.

6. Reduce manual handoffs between systems

Most B2B logistics failures happen at boundaries.

Between ERP and TMS. Between shipper and carrier. Between operations and finance. Between planning and customer teams.

Each handoff introduces delay and inconsistency.

Modern operations focus on:

- Reducing re-entry of data

- Connecting planning, execution, and billing

- Giving every team access to the same shipment truth

This is not about technology for its own sake. It is about removing friction that slows response and creates error.

Read More: Automating Proof-of-Delivery (POD)

7. Measure what actually drives outcomes

B2B logistics teams often track what is easy, not what matters.

Common gaps include:

- No visibility into true cost per customer

- No measurement of exception frequency

- No link between service failures and margin impact

- No insight into dwell and delay patterns

Better teams align metrics with decisions:

- Margin by customer and lane

- On-time performance by facility

- Dwell time by location

- Exception rate by carrier

- Cycle time from order to invoice

These numbers guide strategy, not just reporting.

8. Prepare for disruption as a normal condition

Disruption is no longer an edge case.

Weather, labor issues, geopolitical shifts, port congestion, and carrier instability are part of daily operations.

B2B leaders build resilience by:

- Defining alternate routing in advance

- Maintaining multi-carrier options

- Creating clear escalation paths

- Practicing scenario responses

Resilience is not a document. It is a set of habits embedded in daily work.

Read More: Prepare Your Logistics for Natural Disasters & Trade Interruptions

What strong B2B logistics looks like in practice

Across industries, the best B2B logistics organizations share a few traits:

- They treat logistics as part of the customer experience

- They design networks for variability

- They manage carriers as a system

- They use visibility to drive action

- They standardize core workflows

- They connect systems to reduce friction

- They measure what drives outcomes

- They plan for disruption

These are not technology features. They are operating principles.

Technology simply determines how easy they are to execute.

From friction to flow

Most B2B logistics teams are not limited by trucks or carriers. They are limited by fragmentation.

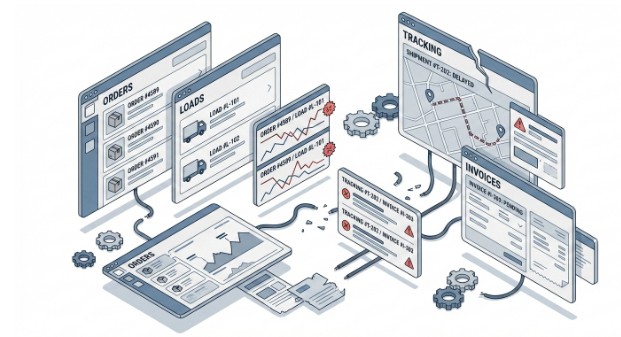

Orders live in one system. Loads in another. Tracking in a portal. Documents in email. Costs in finance. Every exception forces people to stitch reality together by hand. That is why growth feels harder than it should. Every new customer adds complexity. Every disruption becomes a fire drill.

The result is not just inefficiency. It is lost trust, slower decisions, and margin that quietly slips away.

High-performing teams solve this by giving the entire operation one shared source of truth. Planning, execution, visibility, and billing stay in sync. Everyone sees the same shipment story in real time. Exceptions surface early. Decisions happen faster.

That is what FTM is built for.

FTM connects your B2B logistics operation end to end, so your team stops compensating for broken workflows and starts running freight with clarity and control.

If you want to see what that looks like in your own network, book a short demo with the FTM team.

Book a demo at ftm.cloud