Discover proven strategies to reduce freight costs without sacrificing service quality, from smarter routing and automation to TMS visibility.

The Pressure to Reduce Freight Costs, Without Losing Customers

Freight expenses have been rising faster than revenue for most logistics teams. According to industry data from 2024, transportation costs climbed by an average of 11%, driven by fuel volatility, limited capacity, and rising accessorials.

But while shippers and brokers scramble to reduce freight costs, customers still expect perfect, on-time delivery and transparent tracking. That’s the catch: if you cut costs too hard, service quality suffers, and you lose the very clients you’re trying to serve efficiently.

The key is freight cost optimization, not cost cutting. The most successful logistics leaders find efficiencies in planning, routing, visibility, and technology that let them save money and deliver better results.

The Balancing Act: Cost Efficiency Meets Service Excellence

Reducing freight costs doesn’t mean compromising performance. It means identifying where inefficiencies hide, in lanes, load sizes, scheduling, or billing, and fixing them with precision.

Let’s look at practical, data-driven ways to reduce freight costs while preserving reliability and customer satisfaction.

Read more: End-to-End Supply Chain Visibility: Eliminating Blind Spots in Logistics

1. Consolidate Loads and Maximize Trailer Utilization

One of the most effective ways to reduce freight costs is to consolidate shipments and use every cubic foot of your trailer. Combining LTL shipments into FTL or mixing compatible goods on shared routes can lower per-unit costs by up to 20%.

Smart logistics teams also analyze historical lane data to find backhaul opportunities, turning what used to be empty miles into profitable trips.

Tip: Run monthly audits on your top 10 lanes by total cost and load ratio. Look for repeat underutilized routes, that’s where savings live.

2. Mode and Route Optimization

Not every shipment needs to move by road. Many companies cut logistics costs by switching to intermodal transport for less time-sensitive cargo or by planning multi-stop FTL routes to increase efficiency.

By leveraging TMS tools for route modeling and predictive ETAs, you can reduce freight costs and emissions while maintaining strong on-time delivery.

Example: A U.S. manufacturer recently optimized its Midwest distribution routes using TMS-based analytics, reducing total freight cost by 13% while improving OTIF compliance by 4%.

Read more: In-House Fleet vs Outsourced Carriers: Which Scales Best in Logistics

3. Use Automation and Real-Time Visibility

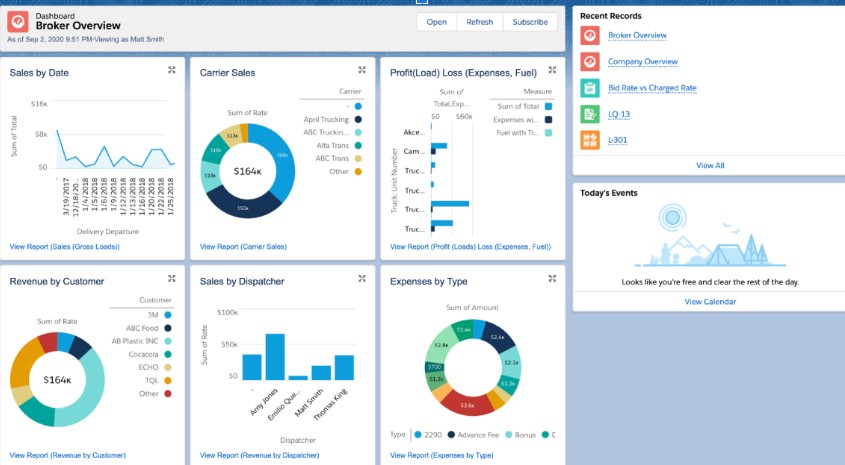

Manual shipment planning, rating, and invoice auditing eat time and inflate costs. A Transportation Management System (TMS) that automates these tasks provides visibility across every shipment and carrier, enabling instant cost analysis.

Automation can:

- Prevent overbilling and duplicate invoices

- Identify cheaper alternative carriers

- Predict exceptions before they cause costly delays

These insights directly reduce freight costs while strengthening service quality through transparency and control.

4. Strengthen Carrier Relationships, Not Just Rate Sheets

In 2025, successful logistics operations thrive on strategic carrier partnerships, not transactional bidding.

Building long-term relationships with reliable carriers lets you negotiate consistent pricing, guaranteed capacity, and service SLAs, while still keeping rates competitive.By sharing forecasts and collaborating on continuous improvement, both sides gain efficiency. Over time, that trust reduces administrative cost, improves transit reliability, and strengthens your brand’s dependability.

Read more: Enhance Carrier Scorecards: Top Metrics to Improve Service Quality and Win More Shipper Bids

Action Plan: Smart Steps to Lower Costs Without Lowering Quality

| Action Step | Expected Outcome |

| Audit top freight lanes by cost per mile | Identify where cost-to-service ratio is weakest |

| Implement automated invoice audits | Reduce hidden fees and accessorials |

| Optimize load consolidation weekly | Improve utilization and lower per-mile cost |

| Use route analytics for low-priority freight | Shift to cost-efficient modes |

| Build carrier scorecards for performance | Ensure reliability even at lower cost |

How FTM Helps You Reduce Freight Costs Intelligently

Balancing cost and service becomes seamless when your tools work together. FTM brings route optimization, rate comparison, and predictive analytics into one unified TMS, giving shippers and brokers the ability to make decisions in real time.

With FTM, you can:

- Analyze lane profitability instantly

- Automate routing and mode selection

- Identify exceptions before they impact customers

- Reduce freight costs through visibility and control

This is about smarter logistics that delivers better service at lower cost.

Read more: TMS Freight Visibility: Enhance Shipment & Carrier Transparency

Cost Reduction Is a Service Strategy

When you reduce freight costs the right way, you aren’t reducing quality, you’re enhancing it. Every optimization you make adds resilience and reliability to your logistics network.

Today’s winners in freight don’t just deliver cheaper; they deliver smarter. If your goal is to improve performance, profitability, and customer trust simultaneously, now’s the time to evolve your strategy.

Book a free demo with FTM today and see how predictive analytics and automation can help you cut costs without cutting service.