Global freight regulation is entering a more complex phase. The change is not driven by a single policy or region, but by a combination of environmental mandates, customs modernization, data governance, and geopolitical pressure.

For logistics leaders, the challenge is no longer awareness. Most teams know regulations are increasing. The real challenge is operational readiness. Regulations now reach deeper into daily execution, affecting routing decisions, documentation timing, data accuracy, carrier selection, and even customer communication.

As 2026 approaches, leaders who treat compliance as a legal or back-office issue will face delays, penalties, and service failures. Those who integrate regulatory thinking into planning and execution will move freight with fewer surprises.

This article outlines the regulatory areas that matter most and what logistics leaders should be preparing for now.

Global regulations are becoming operational, not theoretical

In the past, regulatory change often arrived slowly. Companies had time to adjust processes over months or years. That buffer is shrinking.

Several trends are driving this shift:

- Digitization of customs and trade documentation

- Environmental rules tied directly to shipment data

- Increased enforcement using automated systems

- Reduced tolerance for incomplete or late filings

Regulation is no longer something you check at the border. It is embedded in how freight is planned, tendered, tracked, and invoiced.

Read more: What You Should Expect From Your TMS in 2026

Customs modernization is accelerating worldwide

Customs authorities across major trade lanes are modernizing systems to improve visibility, security, and revenue protection. The result is faster clearance for compliant shipments and harsher consequences for errors.

Key changes leaders should be aware of include:

Pre-arrival data requirements

Many countries now require shipment data well before cargo arrives. Missing or inconsistent data can trigger holds automatically.

Increased use of risk scoring

Customs agencies increasingly rely on algorithms to flag shipments. Inconsistent data, unclear origin details, or unusual routing patterns raise red flags.

Less tolerance for manual corrections

Fixing errors after arrival is becoming harder. Authorities expect data accuracy upfront.

For logistics teams, this means documentation accuracy must improve at the source. Waiting until the shipment is en route is often too late.

Environmental and emissions rules are tightening unevenly

Environmental regulation is one of the most fragmented areas of global freight compliance.

Different regions are moving at different speeds, but the direction is consistent:

- More reporting on emissions by mode and lane

- Financial penalties tied to carbon output

- Pressure to demonstrate reduction strategies, not just reporting

In Europe, emissions tracking and sustainability reporting are becoming mandatory for many shippers. In other regions, similar requirements are emerging through port authorities, customers, or trade agreements.

Logistics leaders should expect sustainability to influence:

- Mode selection

- Carrier selection

- Route planning

- Customer reporting obligations

This is no longer limited to corporate sustainability teams. Transportation teams are now on the front line.

Trade compliance and sanctions are more dynamic

Geopolitical volatility has made trade compliance more fluid. Sanctions, restricted party lists, and export controls can change quickly.

What this means operationally:

- A compliant shipment today may be restricted tomorrow

- Routing decisions can suddenly become non-viable

- Carrier and partner vetting must be ongoing, not annual

Static compliance checks are no longer sufficient. Leaders should expect regulators to hold companies accountable for continuous diligence.

Read more: Why Customer Experience Will Define Logistics Success

Data governance is becoming part of freight compliance

One of the most underestimated regulatory shifts is data governance.

Freight systems now handle sensitive information such as:

- Shipment contents

- Customer identities

- Pricing and contract data

- Location and movement data

Governments are paying closer attention to how this data is stored, shared, and protected. Cross-border data transfer rules are becoming stricter, particularly in regions with strong privacy frameworks.

For logistics leaders, this raises important questions:

- Where is shipment data stored?

- Who has access to it?

- How is access controlled and audited?

- How long is data retained?

These are no longer IT-only concerns. They affect vendor selection and system architecture decisions.

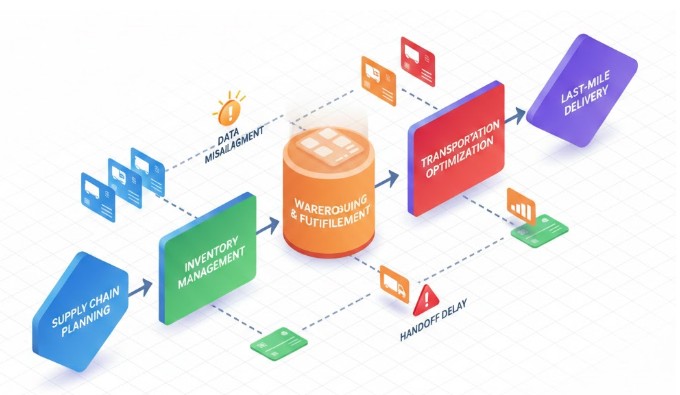

Regulatory complexity increases risk at handoff points

One common pattern emerges across all regulatory categories. Risk concentrates at handoff points.

Examples include:

- Order data moving from ERP to TMS

- Documents transferred between shipper and carrier

- Customs data passed to brokers

- Shipment status updates shared with customers

Each handoff is an opportunity for inconsistency or delay. As regulations tighten, these gaps become more expensive.

Leaders should focus on reducing manual re-entry and improving data continuity across systems.

Read more: Driver Shortage Pressure: What Carriers Should Expect in 2026

What logistics leaders should prepare for now

The most effective responses are practical and operational, not theoretical.

1. Treat compliance as part of execution

Compliance checks should happen as shipments are planned and tendered, not after exceptions appear.

2. Improve data quality at the source

Accurate master data, standardized documentation, and validated inputs reduce downstream risk.

3. Build flexibility into routing and carrier strategies

Rigid networks struggle when regulations change suddenly. Optionality matters.

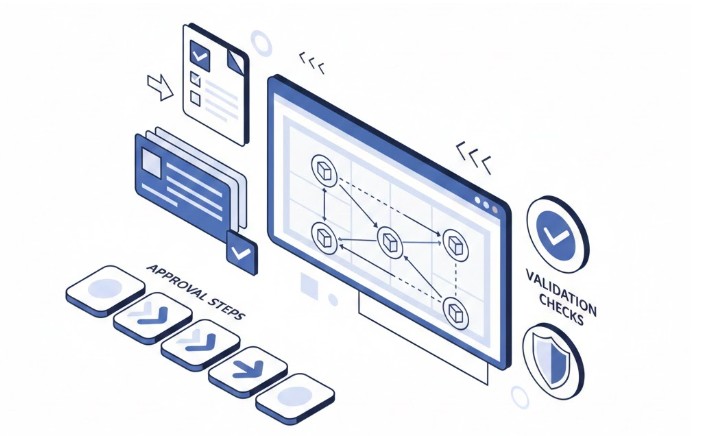

4. Ensure systems support regulatory workflows

Tools should support documentation, validation, audit trails, and reporting without heavy manual effort.

5. Train teams beyond compliance roles

Planners, customer service teams, and operations managers need to understand the regulatory implications of their decisions.

Why technology choices matter more under regulatory pressure

As regulations grow more complex, system limitations become visible faster.

Leaders should evaluate whether their current tools can:

- Surface regulatory requirements early

- Validate documentation automatically

- Support audit-ready data trails

- Adapt quickly when rules change

Manual processes may survive during stable periods. Under regulatory pressure, they break.

Read more: Predictive Maintenance with IoT: Preventing Truck Breakdowns Before They Happen

What this means heading into 2026

The regulatory environment will continue to evolve. Complexity is not a temporary phase.

Logistics leaders who succeed will be those who:

- Anticipate regulatory impact during planning

- Design operations around clean, connected data

- Reduce reliance on manual fixes

- Treat compliance as a performance factor, not an obstacle

The cost of getting this wrong is no longer limited to fines. It shows up as delays, lost customers, and reputational damage.

How FTM supports regulatory readiness

FTM helps logistics teams manage complexity by connecting planning, execution, documentation, and reporting in one system.

With stronger data continuity, configurable workflows, and built-in auditability, FTM supports compliance without slowing operations. That matters as regulations tighten and enforcement becomes more automated.

If your organization is preparing for increased regulatory pressure in global freight, now is the right time to assess whether your systems and processes are ready.

Learn more at FTM or book a quick demo to review your regulatory risk areas and operational gaps.